2025.12.04

2025.12.04  info@zoomjo.com

info@zoomjo.com

Both ball mills and wet pan mills are used for grinding minerals. So, how should customers choose the right mill based on their needs?

The three most critical influencing factors:

1, Investment Budget

The preferred choice for small-scale, low-budget wet pan mill.

Wet pan mill has small processing capacity, but its simple in structure, easy to operate and install, and has high recovery rate.

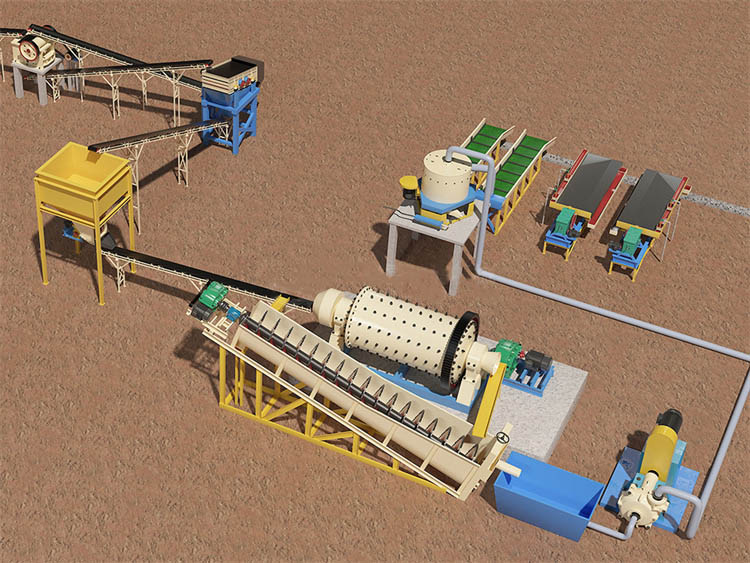

The essential ball mill for large-scale production and investment.

Ball mill high processing capacity with the ability to achieve extremely fine particle sizes. High enrichment efficiency.

2, Ore properties

Containing coarse-grained free gold → Wet pan mill can directly recover it, with distinct advantages.

Fine gold grains encapsulated within sulphide minerals → Requires grinding in a ball mill to achieve liberation, combined with flotation or cyanidation.

3, Application

The wet pan mill is primarily used in small-scale gold mining operations, particularly for rock gold and placer gold.

The ball mill is mainly used in large and medium-sized gold, copper, iron and other metal mineral processing plants.

Actually, in many mineral processing plants, particularly gold ore processing plants in Africa, ball mills and gold mills do not operate as substitutes for one another, but rather as complementary processes.

Common high-efficiency processing flow: wet pan mill → ball mill → cyanidation/gravity separation

This process first uses wet grinding to cost-effectively recover the majority of coarse-grained gold and pre-grind the ore. Subsequently, ball mills are used to finely grind the tailings or coarse concentrate, ensuring the recovery of fine-grained gold. This achieves an optimal balance between overall recovery rates and economic efficiency.