BUSINESS PHILOSOPHY

Science and technology to strengthen the machine, integrity in business

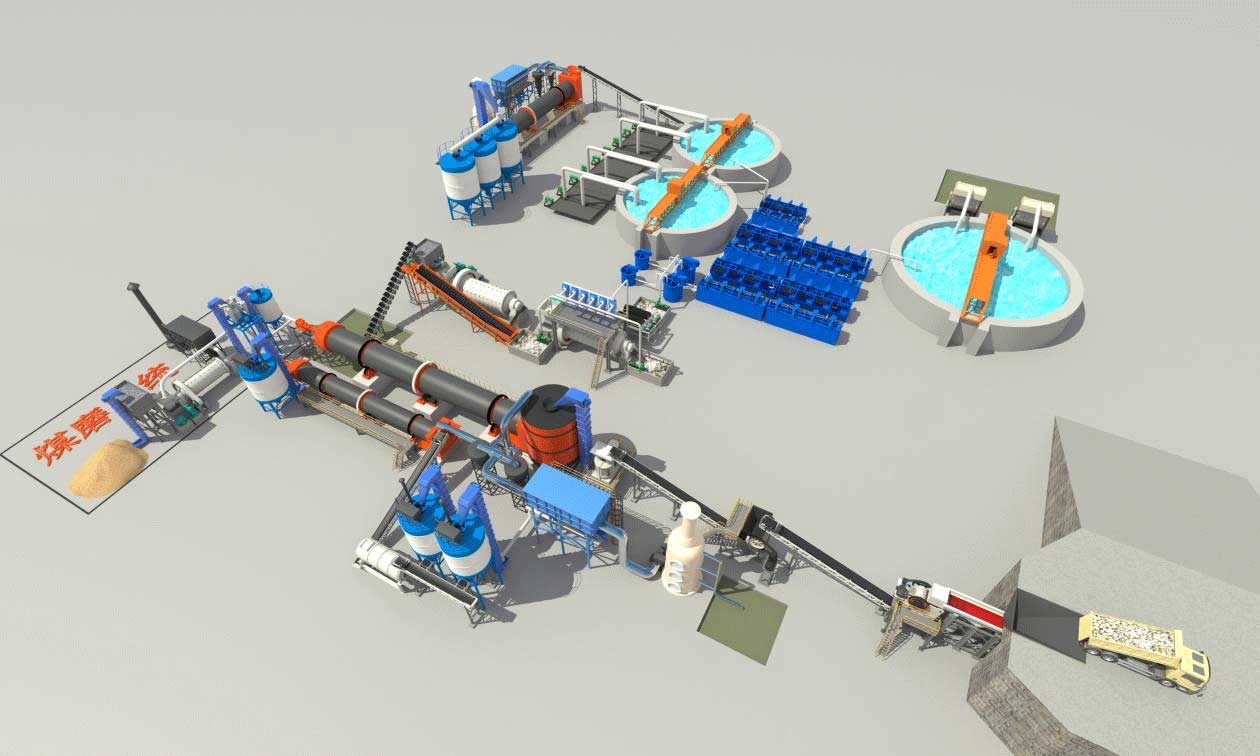

Zoomjo professional manufacturer of gold ore processing equipment, provides gold ore analysis reports and customised turnkey solutions. Different processing techniques are available for extracting gold from various ore types, such as placer(alluvial)gold, rock gold, sand rock, sulphide gold, or other mixed gold ores.

Main gold ore extration beneficiation processes: flotation, gravity separation, cip, cil , heap leaching, etc.

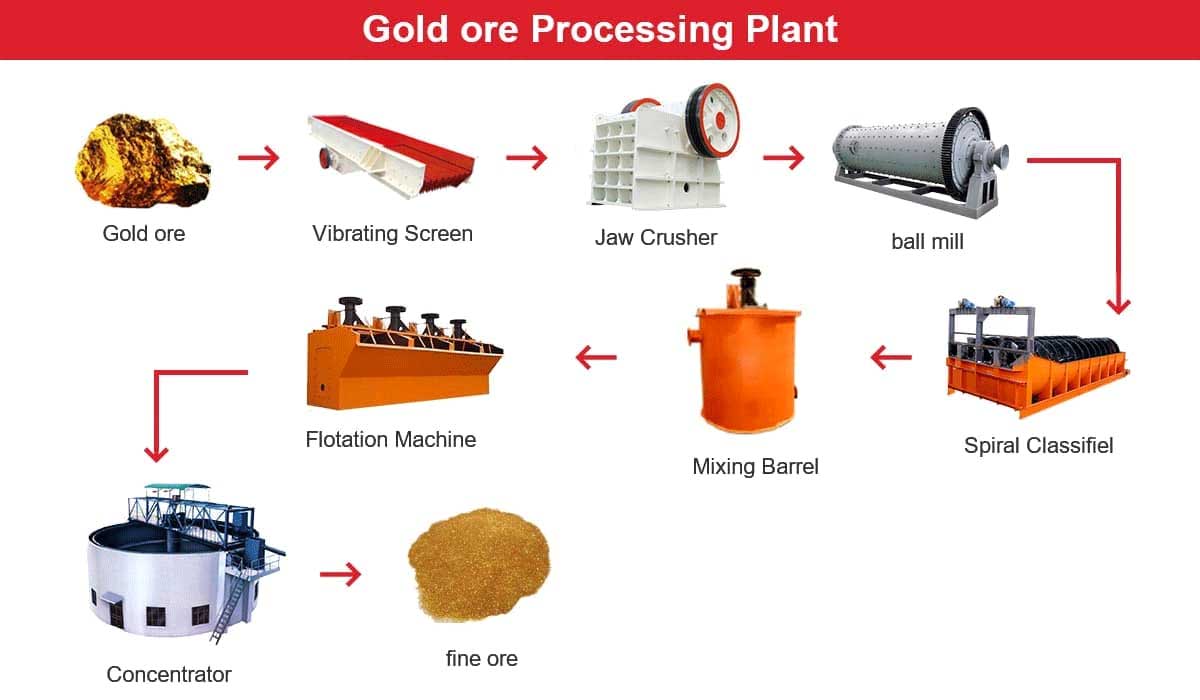

Flotation gold processing

Flotation is the most widely used process for extracting gold concentrate. 80% of rock gold mines use this method for gold beneficiation, with recovery rates as high as 90-97%, and the gold concentrate selected can be sent to smelters for direct smelting.

Main equipment:jaw crusher,vibrating screen, ball mill , spiral classifier,flotation machine, etc.

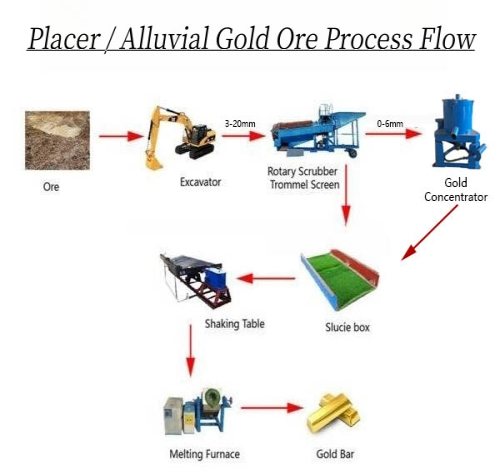

Gravity separation gold processing

①Gravity separation is mainly used for placer gold/alluvial gold washing beneficiation process, also known as gold washing plant, which has simple process, low investment cost and high efficiency.

Main equipment: trommel screen, shaking table, centrifugal gold concentrator, jigging, etc.

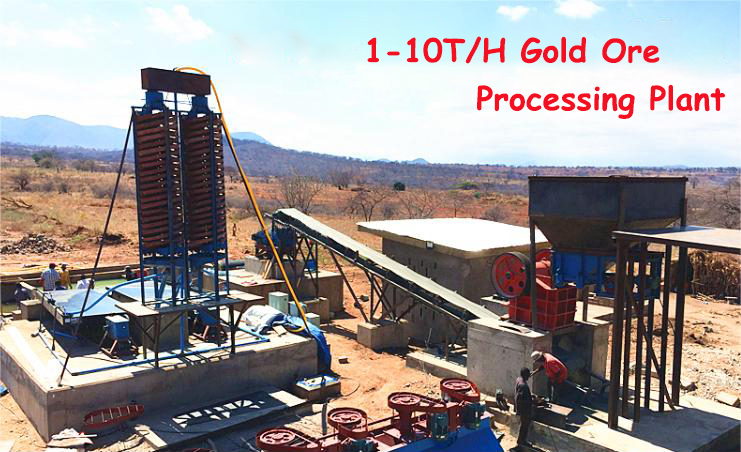

Rock gold ore processing and small gold mining plant equipment .

Carbon in pulp gold processing(CIP)

CIP (Carbon In Pulp)Carbon Pulp Extraction is a filterless cyanidation carbon pulp process for gold recovery by direct adsorption of activated carbon from cyanidation ore pulp. It is widely used in flotation of gold concentrates or amalgamation, re-election of tailings, muddy oxide ores, etc.

Main steps: slurry removal, leaching and adsorption, desorption electrolysis, smelting.

Carbon in leach gold processing(CIL)

CIL (Carbon In Leach) carbon leaching for gold extraction. It is a process where activated carbon is added to the slurry and leaching and adsorption are carried out simultaneously. This process not only simplifies the leaching and cyanidation of the CIP process, but also has low investment, low cost, short infrastructure time, few production steps and small footprint.

Main steps: crushing, grinding, leaching, desorption electrolysis, tailings dewatering

Heap leaching gold processing

Heap leaching is a type of gold extraction by cyanidation, it is mainly used to treat ores with low gold content, the heap leaching method has low production costs and can be put into operation very quickly, the scale of heap leaching can be large or small.

If you want to build an efficient gold plant, please contact us quickly to get the latest gold processing plant costs and solutions.

Welcome to consult whatsapp online +8619511990275 Or leave a message online

Science and technology to strengthen the machine, integrity in business

Quality Assurance, sustainable development

Customer first, mutual benefit and win-win situation

Let the world fall in love with Made in China and enjoy ZOOMJO's services!!!

1500 engineers with more than 30 years of experience in market operation, from equipment selection to capacity optimization and maintenance, tailor-made solutions for users in more than 170 countries and regions.

Service outlets throughout the country, for your lightning delivery,fast supply of all machine products and supporting products of common parts, fragile parts.